Application of Other Parts

of the Code to Class 1, 2, and 3 Circuits

Spread of Fire

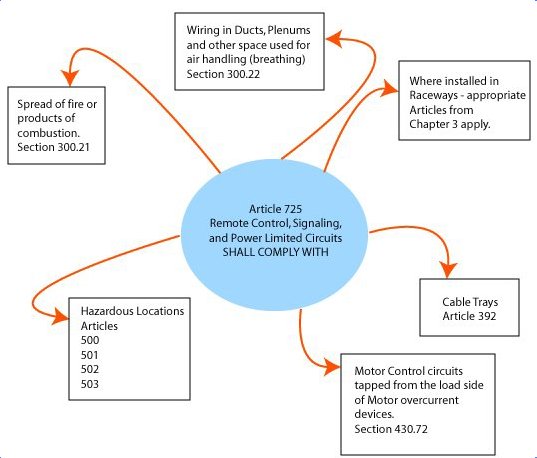

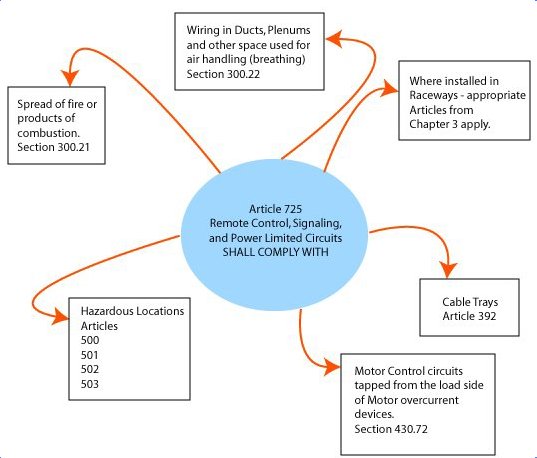

igure 1 graphically illustrates requirements that must be kept in mind when

doing control wiring subject to the Code. Section 300.21 requires that

fire stopping be restored when fire rated walls, ceilings and floors are penetrated.

This requires, in most cases, that a listed fire stopping method be used.

This may require using a fire stopping caulking compound or other more elaborate

assemblies used with cable tray penetrations. The UL Fire Resistance

Directory describes many fire stopping methods and assemblies that have been

tested and listed. These tests measure the time it takes for the temperature

to rise to a specific temperature on the far side away from the fire for

a specific fire rated assembly, and the time it takes for the flames to pass

through the assembly.

igure 1 graphically illustrates requirements that must be kept in mind when

doing control wiring subject to the Code. Section 300.21 requires that

fire stopping be restored when fire rated walls, ceilings and floors are penetrated.

This requires, in most cases, that a listed fire stopping method be used.

This may require using a fire stopping caulking compound or other more elaborate

assemblies used with cable tray penetrations. The UL Fire Resistance

Directory describes many fire stopping methods and assemblies that have been

tested and listed. These tests measure the time it takes for the temperature

to rise to a specific temperature on the far side away from the fire for

a specific fire rated assembly, and the time it takes for the flames to pass

through the assembly.

When boxes are installed on opposite sides of a fire rated wall they are

usually required to have a 24 inch separation. This is not a Code rule

but is found in building codes. To make sure that the fire ratings are

maintained it is practical to consult with the building code official in

charge to learn about any additional local rules or regulations. Throughout the Code there are no exceptions for

restoring the fire rating after a penetration has been made.

The fire rating of a wall may be compromised by installing a flush mounted

panel in the wall unless some approved method is used for the installation.

One approved method that has been used is to line the panel cavity with

sheet rock equivalent to that used on the walls. However, the

installer is again advised to consult with the local authority having

jurisdiction for approved methods.

Wiring in Ducts Plenums and Other Spaces Used for Environmental Air

The Code has some very strict requirements when wiring is installed in air

handling spaces. These spaces have the capacity to rapidly spread fire, and for environmental air, air that is

breathed, there is the danger of spreading toxic products of combustion and

impairing vision in a fire fighting

or egress situation. Therefore plastic coating on wires and cables

are required to be plenum rated and listed when cables are installed in ducts,

plenums, or other space used for environmental air. Since Plenum rated

cables are about three times as expensive as non plenum rated cables it is

a common practice to avoid wiring in these spaces.

2005 Code Change

A change in the 2005 NEC section 300.22(B) removes permission to use liquidtight

metal conduit of any length inside of ducts and plenums used for

environmental air. Article 100 defines a plenum as a compartment or

chamber to which one or more air ducts are connected and that forms part of

the air distribution system. The air handler unit shown above

satisfies this definition and is clearly a plenum. In the past it has

been common practice to use liquidtight flexible metal conduit to connect

power to exhaust and supply fan motors, dampers, temperature sensors, and

other control devices in these units that are used for environmental air.

This practice is no longer permitted by the 2005 NEC.

Hazardous Locations

When Class 2 circuits are installed in a normally dry location away from

flammable gasses and vapors, and away from combustible fibers and ignitable

dust such as in a flour mill the circuit is considered safe from being an

ignition source and from causing severe shock or burns. However, a

Class 2 circuit or a Class 3 and especially a Class 1 circuit is a

source of ignition for flammable vapors and gases such as gasoline vapors.

Extensive rules are in the Code for wiring in hazardous locations are found

in Articles

500, 501, 502, 503, 504, 505,

510, 511, 513, 514, and 515.

Some of these areas require explosion proof enclosures are designed to contain an explosion and

cool discharging gases to below the ignition temperature of the surrounding

atmosphere. There are also many rules on installing sealoffs to prevent

hazardous gases and vapors from spreading from

classified areas to nonhazardous areas through the raceways.

Wet NonHazardous Locations

Many homeowners replace a 24 volt Class 2 circuit thermostat or a door

bell push button operating from a 12 volt Class 2 power supply without

starting a fire and without getting shocked as long as they are working on

the load side of the class 2 power supply. It is interesting to note

that door bell buttons can become wet and that 12 volts is used for door

bells instead of 24 volts. Charles Dalziel's experiments in the early 1940's demonstrated that while 24 volts

is safe in a normal dry environment, in a wet environment the voltage must

be lowered to no more than 15 volts to be safe for humans. Charles Dalziel

actually used human guinea pigs for some of his experiments.

A Visit with Charles Dalziel

he year is 1941. You are an assistant professor of Electrical Engineering

at the University of California, Berkeley. You are awarded a grant by the

California Committee on Relation of Electricity to Agriculture. Purpose: To

find the effects of sub lethal electrical currents on the human body. You

decide to use healthy human subjects. The subjects are given physical examinations

and electrocardiograms. Only subjects in good physical condition are used.

Subjects grasp a 12 inch length of bare copper No. 6 wire in one hand and

the other hand is placed on a brass plate. Current is passed through the

person from the left hand to the right hand. The subject is asked to drop

the wire. After dropping the wire the experiment is repeated using more current,

again and again, until the subject can no longer keep his hand on the eight

inch diameter brass plate. Assistants are then used to hold the subjects

hand on the brass plate and the experiment continues until the subject can

no longer drop the wire because he cannot let go. This experiment is repeated

with 28 subjects and the maximum let-go currents are tabulated and analyzed.

Frequencies are changed from 60 cycles per second to 180 cps, then 500 cps,

then to 1000 cps and the experiments are repeated. It is found that the average

60 cycle let-go current for men is 16 milliamperes and the average let-go

current for women is 11 milliamperes.

he year is 1941. You are an assistant professor of Electrical Engineering

at the University of California, Berkeley. You are awarded a grant by the

California Committee on Relation of Electricity to Agriculture. Purpose: To

find the effects of sub lethal electrical currents on the human body. You

decide to use healthy human subjects. The subjects are given physical examinations

and electrocardiograms. Only subjects in good physical condition are used.

Subjects grasp a 12 inch length of bare copper No. 6 wire in one hand and

the other hand is placed on a brass plate. Current is passed through the

person from the left hand to the right hand. The subject is asked to drop

the wire. After dropping the wire the experiment is repeated using more current,

again and again, until the subject can no longer keep his hand on the eight

inch diameter brass plate. Assistants are then used to hold the subjects

hand on the brass plate and the experiment continues until the subject can

no longer drop the wire because he cannot let go. This experiment is repeated

with 28 subjects and the maximum let-go currents are tabulated and analyzed.

Frequencies are changed from 60 cycles per second to 180 cps, then 500 cps,

then to 1000 cps and the experiments are repeated. It is found that the average

60 cycle let-go current for men is 16 milliamperes and the average let-go

current for women is 11 milliamperes.

Your name is Charles Dalziel and you have just begun. You will establish

criteria on fibrillation currents using dogs, pigs, calves, and sheep. You

become the authority on dangerous electric currents. Your experimentation

will establish the principles for protecting persons from the hazards arising

from the use of electricity, and your findings will be used for the notes

to the Tables in Article 725 of the National Electrical Code.

|

When Class 2 circuits are installed in a hazardous location they must

be installed just like power circuits in a hazardous location unless the

circuits are also rated as intrinsically safe or nonincendive. Intrinsically

Safe circuits have specific requirements in the Code in Article 504. Unless intrinsically safe circuits have been also tested and listed as Class

2 circuits, they are not Class 2 circuits.

|

Myths and Falsehoods about Intrinsically Safe Circuits and Systems

Myth number 1: Intrinsically Safe Circuits are something new.

Many of us got our first glimpse of an intrinsically safe circuit

with the addition of Article 504 to the 1990 National Electrical Code. We

thought this might be something new. This is the first myth. No, intrinsically

safe wiring is not new. It has been around since the 1930's. It all started

because of a mine accident in England in the early l900's. Work began on

intrinsically safe systems in England in 1911, and by the 1940's certified

intrinsically safe systems were available for the industrial market.

Myth number 2: Intrinsically safe circuits are also Class 2 circuits.

This is a common sense statement that is often made by people that

do not know the difference between a Class 2 and an intrinsically safe circuit.

After all, if an intrinsically safe circuit will not release enough energy

to ignite a flammable mixture of gasoline, surely it will not cause a shock

or be an ignition source in a nonhazardous location. But, the fact is, AN

INTRINSICALLY SAFE CIRCUIT IS NOT NECESSARILY A CLASS 2 CIRCUIT. The two circuits

are tested to different standards. Basically, an intrinsically safe circuit

is suppose to not cause an ignition of a flammable mixture under any two

fault conditions occurring simultaneously while a class 2 circuit is not

supposed to shock anyone or be a source of ignition in a nonhazardous location

when any number of faults occur. An intrinsically safe circuit is not a Class

2 circuit unless the power supply is durably marked Class 2 as required by

the NEC. This does not mean that someone can just mark the power supply Class

2; it means that the power supply must be tested and Listed as a class 2

power supply.

Myth number 3: Intrinsically Safe circuits can be wired as a class

2 low voltage circuits.

If the intrinsically safe circuit is also a class 2 circuit then

the class 2 wiring methods can be used. But if the intriinsically safe circuit

is not a Class 2 circuit - Watch Out! This means that the intrinsically

safe circuit is more than likely a Class 1 circuit, and Class 1 circuits

must be wired like a normal power circuit using the wiring methods of Chapter

3 of the NEC. This means that splices must be in boxes. Open terminals are

not allowed, and 22 gauge wires are not allowed. That's right, if an intrinsically

safe circuit is not a class 2 or class 3 and is not a motor control circuit

as defined in section 430.72, we are left with only one option for a remote-control,

signaling, or power limited circuit: it must be a Class 1 circuit by default

. This means the minimum wire size is No. 18 or other sizes if in a

listed class 1 cable. It also means all the relief given for Class 2 circuits

in Article 725 do not apply. The intrinsically safe circuit may not ignite

the most easily ignitable mixture of gases or vapors for which it is designed

for, but it still may be a shock hazard to humans, and therefore, must be

wired accordingly.

|

Where installed in Raceways Applicable Articles in Chapter 3 Apply

The raceway fill requirements of chapter 3 apply to Class 2, Class 3, and

Class 1 circuits. No derating is required for control and signaling

circuits and likewise for Class 2 circuits. Under some conditions,

derating may apply to Class 1 circuits. The raceway sections that require

support apply as do all the other requirements.

Page 6

igure 1 graphically illustrates requirements that must be kept in mind when

doing control wiring subject to the Code. Section 300.21 requires that

fire stopping be restored when fire rated walls, ceilings and floors are penetrated.

This requires, in most cases, that a listed fire stopping method be used.

This may require using a fire stopping caulking compound or other more elaborate

assemblies used with cable tray penetrations. The UL Fire Resistance

Directory describes many fire stopping methods and assemblies that have been

tested and listed. These tests measure the time it takes for the temperature

to rise to a specific temperature on the far side away from the fire for

a specific fire rated assembly, and the time it takes for the flames to pass

through the assembly.

igure 1 graphically illustrates requirements that must be kept in mind when

doing control wiring subject to the Code. Section 300.21 requires that

fire stopping be restored when fire rated walls, ceilings and floors are penetrated.

This requires, in most cases, that a listed fire stopping method be used.

This may require using a fire stopping caulking compound or other more elaborate

assemblies used with cable tray penetrations. The UL Fire Resistance

Directory describes many fire stopping methods and assemblies that have been

tested and listed. These tests measure the time it takes for the temperature

to rise to a specific temperature on the far side away from the fire for

a specific fire rated assembly, and the time it takes for the flames to pass

through the assembly.